This article originally appeared on the website World Financial Review on November 20, 2021, under the title Green Development LLC Explains Why We Need to Shift to a Circular Economy.

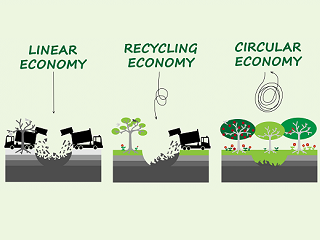

The global economy produces billions of tons of waste each year due to the mostly linear manner in which precious natural resources—minerals, ores, fossil fuels, and biomass—are extracted and utilized as inputs for products. Approximately two-thirds of those raw materials are converted into waste within the manufacturing process. And only nine percent of finished products are recycled. But what if we could find a way to avoid much of the waste or the need to recycle? At the very least, what if we could re-use a much higher percentage of the waste materials to create new products of equal or higher quality?

A circular economy is an alternative approach to the linear “take-make-dispose” model that humanity has relied upon since the Industrial Revolution. It is estimated that decisions made at the design stage of the manufacturing process determine 80% of a product’s environmental impacts. At its core, a circular economy targets the design stage of manufacturing to extend the life of materials and products. It transforms our current linear model into a continuous cycle of quality reconstruction to significantly reduce waste, by employing various tactics, including sharing, leasing, reusing, repairing, and remanufacturing. In this article, Green Development LLC highlights several strategies of a circular economy and how governments, companies, and individuals are and can continue to move towards this new socio-economic architecture.

Why the Conversation Has Changed

As of 2021, estimates place the world population at 7.9 billion; according to the United Nations, it is estimated to reach 9.7 billion by 2050 and potentially peak at 11 billion in 2100. This projection places unprecedented demand on the supply of finite raw materials, especially for natural resource-poor countries dependent on trade and, therefore, the transportation of goods. The inevitable increase in production presents a complex matrix of challenges, both to governments and businesses, as the world struggles to implement solutions to grapple with the threatening effects of global warming and rising geo-economic tensions. It is becoming increasingly clear that without change to the current system, the trajectory is not sustainable.

Upcycling vs. Downcycling: Why Recycling Isn’t Good Enough

To understand why a circular economy is so critical, we need to understand the waste products that come from traditional recycling methods. Typically, recycling involves putting energy into a system—often with pollution as an unintended output—to mix different used products and create a hybrid product of lower quality than the original products. These new products are ultimately more challenging to recycle when their time comes and are likely to end up in landfills as their quality degrades with repeated recycling processes (if any). This low-value, high-energy loop is called downcycling.

In contrast, upcycling reuses waste without damaging the original materials, thereby preserving the quality of materials. Products in a circular economy are designed to ultimately be upcycled—retaining their chemical integrity and even enhancing their overall manufacturing value. Everything, from the materials used to recycling methods, must be taken into account from the product’s design stage. In addition, circular economy products are also engineered with the intention of being easier to maintain and repair before they are upcycled, overall contributing to an extended product lifecycle.

Putting Principles into Action

Businesses are responding with innovative approaches to modifying their products and filling gaps in the market with products that fit this narrative. Green Development LLC has taken note of several major efforts by companies in this field.

Auto manufacturer BMW has set an exciting new precedent embracing the circular economy lifecycle for its vehicles. Though it hasn’t been released to the commercial market just yet, BMW manufactured a car made entirely of recycled, reused, and renewable materials. Furthermore, the company will adhere to vehicle designs that can be completely disassembled at the end of the product’s lifecycle, with all components reused and recycled.

Group Renault is another pioneer of the circular economy in the automotive industry. The company’s remanufacturing initiatives, which involve restoring engine parts from reclaimed old cars, such as gearboxes and turbo compressors, generated nearly €120 million in revenue in 2019. Environmental benefits from these circular endeavors are notable as well, using 80% less energy, 88% less water, 92% fewer chemical products, and 70% less waste than traditional automotive production methods.

The international home goods chain IKEA is aiming to become 100% circular by 2030. IKEA currently offers spare parts to extend the life of its products, is committed to using only renewable or recycled materials by 2030, and is introducing a buy-back scheme for customers to return their old products that will then be used to generate new products by IKEA.

3D printers present endless opportunities for creating products with minimal waste, and they can also be used to help with repairs and extend the lifecycle of products. Dagoma, a 3D printer company based in France, has launched a project called Toy Rescue, which supplies designs to 3D print replacement parts for toys.

Imperatives for Future Success

The World Economic Forum reported that in 2019 alone, over 92 billion tons of material contributed to about half of global carbon dioxide emissions in our current linear economy. According to a 2019 paper released by the Ellen MacArthur Foundation in collaboration with Material Economics, implementing a circular economy for just five key sectors—cement, aluminum, steel, plastics, and food—would eliminate 3.7 billion tons of emissions by 2050 and move us further towards a future with net-zero carbon emissions before we hit irreversible levels of global warming.

In 2017, the World Economic Forum’s Circular Economy Initiative launched its Platform for Accelerating the Circular Economy, consisting of 80 public, private, international, and civil society executive leaders and over 200 members globally. The Forum has prioritized transforming the material value chains to create circular production cycles for plastics, electronics, batteries, cars, and textiles.

Following these advances, the European Union introduced a circular economy action plan under the European Green Deal in March 2020. Only a year later, it amended the original plan with additional measures to achieve a fully circular economy by 2050.

Committing to Zero Waste

According to a National Renewable Energy Laboratory (NREL) publication from 2020, as economies incorporate more renewable energy generation and storage, novel materials coupled with innovative manufacturing strategies will be required to embrace a zero-waste model. A significant portion of present-day renewable energy technology is complex, difficult to deconstruct, and cost-prohibitive to remanufacturing and recycling. However, this is changing, as the Wind Energy Technologies Office (WETO) is working across the industry to prioritize a circular economy, specifically with wind blade recycling. The University of Tennessee and Carbon Rivers, funded by WETO, is developing a process to reclaim the fiberglass from decommissioned wind turbine blades which will see new life as second-generation composites across multiple industries.

To achieve a circular economy, governments, businesses, and consumers will have to work together. Governments will need to implement policies that require or encourage companies to meet specific criteria for their products. In turn, consumers will have to commit to purchasing products designed with upscaling in mind, repairing broken products when possible, responsible recycling, and voting with their wallets by purchasing from companies committed to circular development processes.